Fluid Bed System Applications

An ACT fluid bed sends a powerful stream of air up through your particulate material, suspending and circulating the particles like a boiling fluid. This churning action, or “fluidization,” produces an even distribution of air among the particles, making the fluid bed perfect for heating, cooling, or drying processes. The fluidized particles can also be easily and evenly coated or otherwise treated using a variety of techniques. And since the fluid action is achieved using nothing more than air, your material is handled as gently as possible. Whatever your production needs, ACT fluid beds offer a proven, low cost solution.

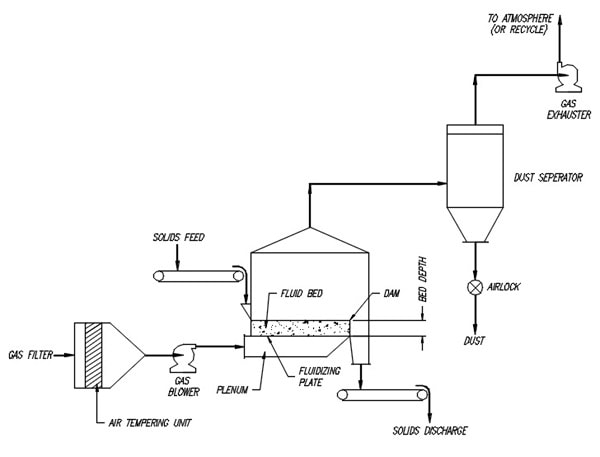

Continuous Fluid Bed System