Designed for your Granulation/Agglomeration Process

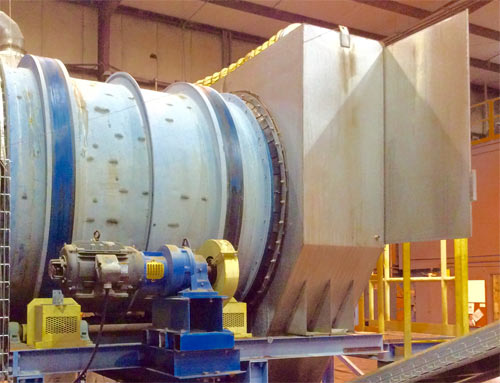

Our Rotary drum granulators are manufactured with quality and safety in mind. Each drum is built by our team of engineers, designers, and craftsman who together have more than 300 years of experience in granulation technology. In addition, our on-site laboratory and pilot plant equipment and facilities produce the data needed to design and size your rotating granulator for your own process.

We understand that your rotary drum granulator/agglomerator may require specialized internals. We have the experience and expertise to help you with the special internals that your process needs. We also build granulation drums that perform functions in addition to granulation such as drying, classifying, and coating. In addition to the rotary drum itself, we design granulation systems that may include air handling, product screening and recycle, drying, and more.

Rotary Granulator

Materials of Construction: Carbon Steel, Stainless Steel, and Specialty Alloys

Diameters: 1 foot to 14 foot diameter

Lengths: Up to 60 feet (single segment), Up to 150 feet (multiple segments)

Air Handling/ Emissions Control Systems Available:

- Scrubbers

- Baghouses

- Cyclones

- Combination of the Above