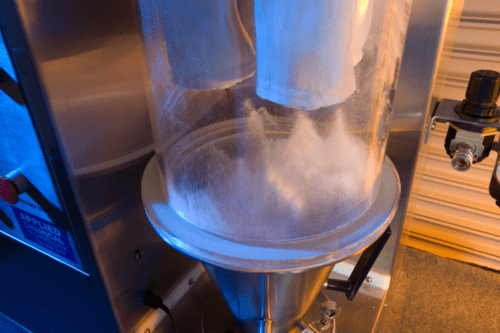

Equipment for Liquid and Powder Coatings and Impregnation

ACT fluid bed coaters are manufactured following the highest quality and safety standards. Each fluid bed is built by our team of engineers, designers, and craftsman with expertise in fluid bed technology since 1981. In addition, our in-house laboratory and pilot plant equipment and facilities generate the data needed to design and size your fluidized bed coater to meet your process specifications.

We are aware that your coating process may require specialized fluid bed design. With experience in fluid bed design beginning in 1981, we have the knowledge to help you with your process development and equipment needs. We build both batch and continuous fluid bed coating machines. We also build fluid beds that include zones for multiple unit operations. These zoned fluid bed coaters may include drying, classifying, granulating, and more. In addition to fluid beds, we design and build complete fluid bed systems.

Sizes: ¼ ft2 to 1000 ft2

Capacities: 4 lbs/hr to 50 tons/hr

Air Handling/ Emissions Control Systems Available:

- Scrubbers

- Baghouses

- Cyclones